-

About us

-

About us

-

About us

Our company was funded on 1960; and by 1996 it became one of Guatemala's major knit supplier.

We specialize in the production and sales of knitted fabrics and full package apparel. Imperial employs over 1,600 people on its production stage.

We are one of the few vertical manufacturers in the region, with its own spinning mill. Our operation involves five major activities: first, Design Capabilities; second, EDI – Replenishment; third, Yarn Spinning; fourth, Knitting; and fifth, Piece Dyeing-Finishing.

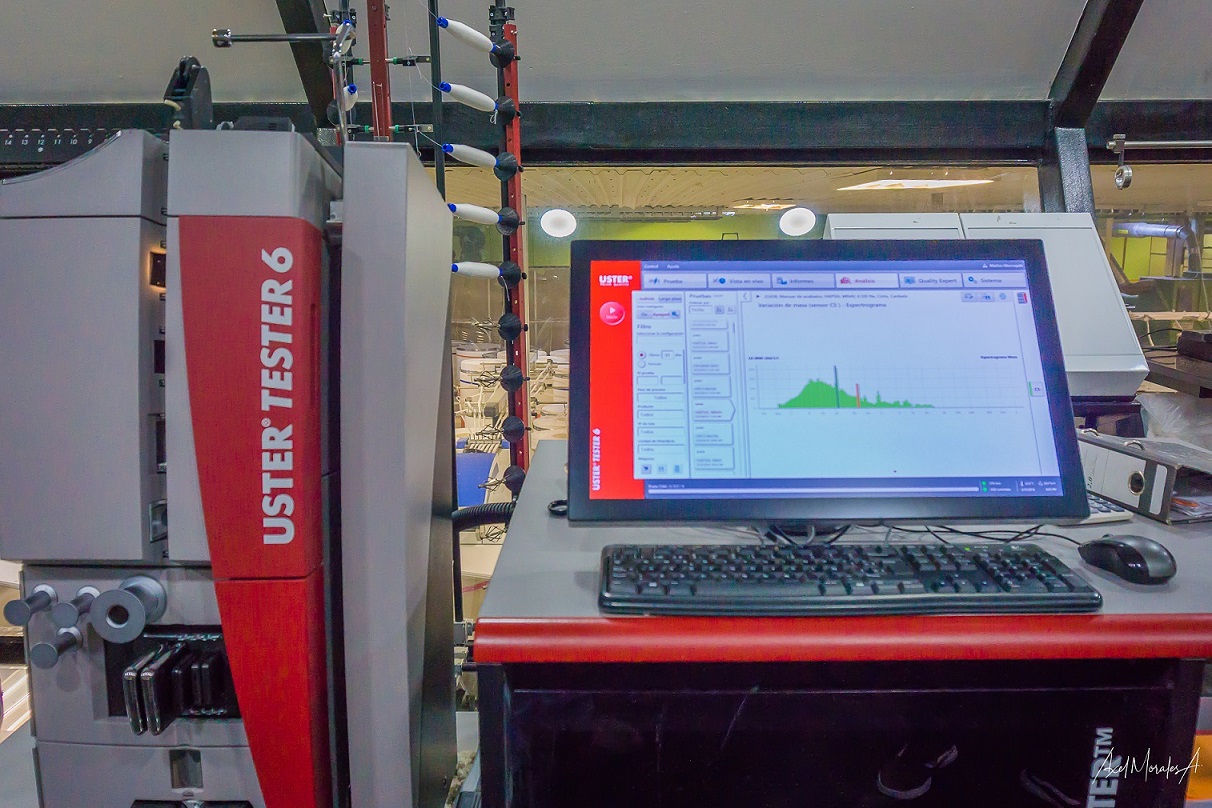

One of the few companies in the region with its own spinning mill and extended expertise of cotton yarn products.

One of the few companies in the region that has their own spinning mill. Extended knowledge on cotton yarn, and production of most blends are possible.

Ring spun yarn; with a daily production capacity of 80,000 lbs.

FIBERS

COTTON

-U.S. Cotton

POLYESTER

-Recycled Polyester, White Polyester, OB Polyester.

RAYON

-White Rayon

Production of various cotton and polyester blends.

-Classic blends

-100% Cotton or Polyester

-Cotton/Polyester Bi-Blends

-Tri-Blends

-Special Effects

Extended knowledge base on 100% U.S. cotton yarn

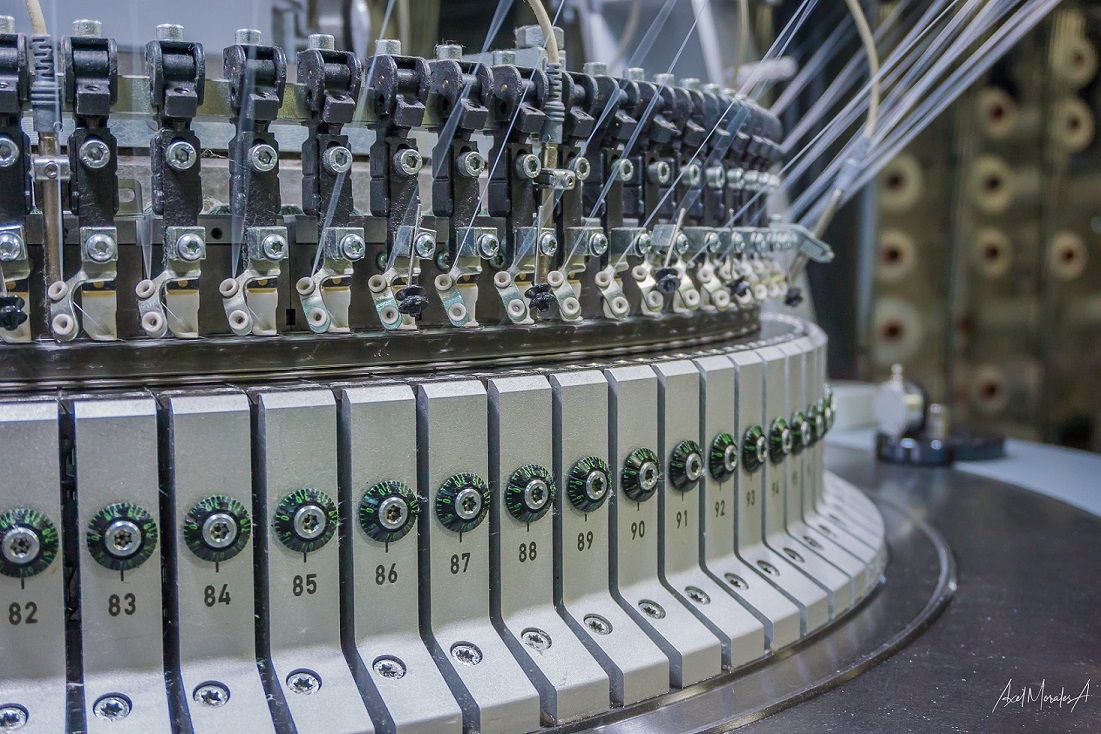

Imperial group has the capabilities and experience on a wide variety of weft knitted products.

We have the capabilities and experience on a wide variety of weft knitted products. Production and development, per customer request, of all weft knitted products. Among them are: Jersey, Fleece, Interlock, Piqué, Micro piqué, Ribs & Feeder Stripe.

Monthly production capacity of 1.4 million pounds of any knitted fabric.

Single and double knit machines for any knitted fabric design; most of them from major German brands with the latest technology on Electronic Fault Detector technology using high quality needles.

Production and development, per customer request, of all weft knitted products. Among them are: Jersey, Fleece, Interlock, Piqué, Micro piqué, Ribs & Feeder Stripe.

Our group has invested on the most advanced and fully automated dyeing finishing machinery and roller printing ensuring the best quality.

Our group has invested on the most advanced and fully automated dyeing finishing machinery and roller printing ensuring the best quality.

Monthly production capacity of over 1.65 million lbs of dyed and finished textile products.

We work on and supply several dyed and finished products. Among the services provided are: Wicking, UV, Anti microbial, Bio polish, roller printing, peaching among others.

Fully automated machinery, reducing manual interference. We have one of the best regional inhouse laboratories. Automated chemical dispensing and control systems to ensured color repeatability.

Imperial group works and schedule production lines to supply garments with the maximum productivity and the highest quality standards.

Full package service is available with costing takes one to two days, lab dips 3 or 4 days and customer orders delivery time raging between 6 and 8 weeks.

We have a full inhouse laboratory to fully inspect fabric before been sent to the garment assembly process. Computer generated markers are used to guarantee low fabric waste and optimize production costs.

Preproduction details are review prior beginning production. All critical details of garments are thoroughly discussed by our Quality Control department.

As a large vertical manufacturer, Imperial group is involved in various products. Upon approval, delivery time of new orders takes about 8 weeks and replenishment order about 5 weeks

Imperial Group is focused on improving the productivity of all business lines